The Benefits of PCB Test: Ensuring Quality and Reliability

Are you familiar with pcb test? If not, let me introduce you to this essential process in the world of electronics manufacturing. pcb test plays a crucial role in ensuring the quality and reliability of printed circuit boards (PCBs). In this article, we will explore different testing methods, the importance of pcb test, and how JinHua’s tailored solutions can benefit your business.

Various PCB Testing Methods

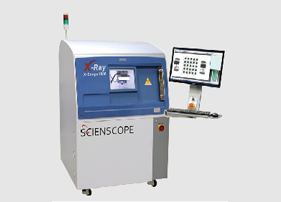

There are several testing methods employed during the production of PCBs. These include automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and burn-in testing. AOI uses cameras to detect defects such as soldering issues or component misalignment. ICT checks for electrical faults by probing individual components on the board. Functional testing verifies if the assembled board performs its intended functions correctly. Burn-in testing involves subjecting the boards to extreme conditions to identify potential failures under stress.

The Importance of PCB Test

PCB test is vital because it ensures that each board meets specific quality standards before reaching customers’ hands. By identifying any manufacturing defects early on, companies can prevent faulty products from entering the market and damaging their reputation. Additionally, thorough testing helps minimize product recalls and warranty claims due to defective boards.

JinHua’s Tailored Solutions

JinHua specializes in providing tailored solutions for all your PCB needs. With their expertise in design verification, they ensure that your boards meet industry standards through rigorous tests at every stage of production. Their state-of-the-art facilities enable comprehensive AOI inspections, precise ICT measurements, reliable functional tests, and effective burn-in procedures.

Find more about pcb testing methods.Beyond standard tests, JinHua offers customized solutions based on your specific requirements. Whether you need specialized testing for high-frequency applications, complex assemblies, or unique form factors, JinHua can develop a tailored approach to meet your needs. Their commitment to quality and reliability ensures that your PCBs perform flawlessly in the field.

Conclusion

In conclusion, PCB test is an essential process that guarantees the quality and reliability of printed circuit boards. By employing various testing methods such as AOI, ICT, functional testing, and burn-in testing, manufacturers can identify defects early on and prevent faulty products from reaching customers. With JinHua ‘s tailored solutions and expertise in design verification, businesses can ensure their PCBs meet industry standards while also accommodating specific requirements. So why compromise on quality when you have access to reliable PCB test services?